The smallest possible footprint

As a manufacturer we & our associated Ink Partner are engaged in a continuous process to reduce our impact as much as possible. This means saving energy, water and chemicals is a priority. We purify our water and air before it leaves our factories and we process our waste responsibly, compliant to local regulations and standards. Our scope in sustainability extends to the production sites of our customers as wel. We help them to reduce the environmental footprint of textile printing with products and expert advice, to save energy, reduce emissions and prevent waste of precious resources

Digital drametically reduces waste

The core benefit of digital printing is flexible on demand production. No need to push large quantities with longer lead times and risks of overstock or shortages. Customers can order smaller batches and simply re-order successful collections. Digital dramatically reduces the waste of resources required to produce and ship stocks that never reaches any consumers. Next to that, HGS Machines has instilled a long-term sustainability strategy on its entire operation, impacting everything we do today and tomorrow.

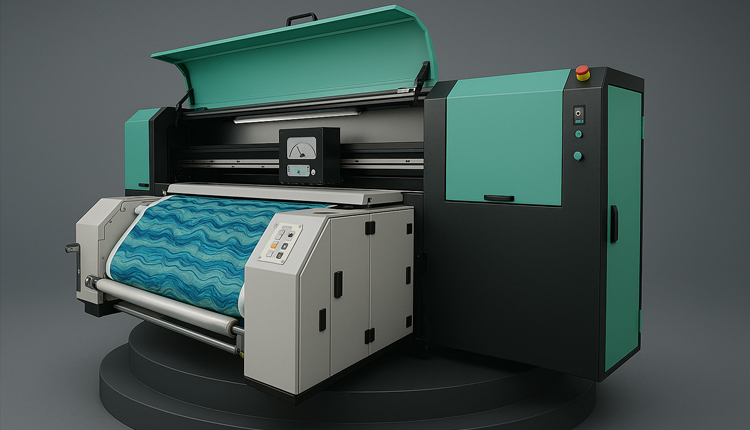

Leopard is the optimal solution for your entry into digital printing

At HGS we have put 2 decades of our experience in textile printing into proven digital technology to help you meet the demands of today's fashion industry. Leopard provides industrial performance and more sustainable, high quality digital printing at a profitable cost level. With fast turnarounds and full application support, Leopard is the optimal solution for your entry into digital printing.