Textile Digital Printing on Fabric: The Future of Fabric Printing

In the world of fashion and textiles, designs keep changing every season. Brands need fast, flexible, and high-quality printing methods that can bring creative ideas to life without wasting fabric or time. This is where textile digital printing on fabric is making a big difference.

Earlier, printing on fabric was mostly done through traditional methods like screen printing or block printing. These methods were time-consuming, expensive for small batches, and limited in design detail. But now, with textile digital printing on fabric, you can print any image, pattern, or color directly onto the cloth using a digital printer—just like printing a photo from your computer.

In this blog, let’s explore everything about textile digital printing on fabric, how it works, its benefits, applications, and why it’s quickly becoming the go-to choice for the textile industry.

What Is Textile Digital Printing on Fabric?

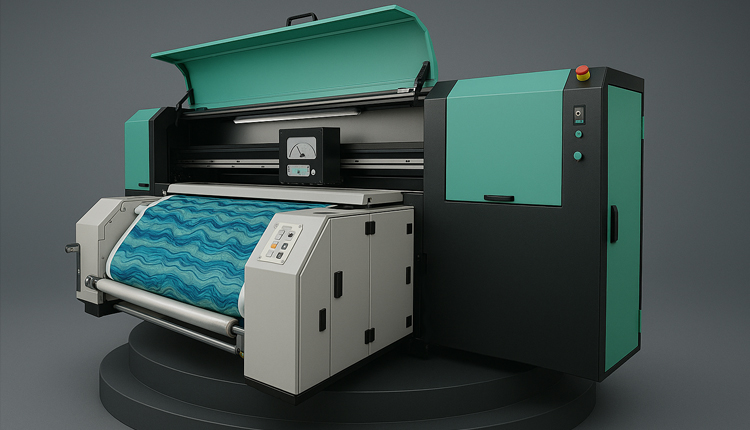

Textile digital printing on fabric is the process of using advanced inkjet technology to print designs directly onto textiles. Unlike traditional printing, there is no need for screens or plates. The design is prepared on a computer and printed straight on the fabric using special inks.

The printer sprays the ink directly on the fabric surface, and the fabric is then heated or steamed to fix the color. This method gives sharper, more vibrant prints, even for complex or colorful designs.

In simple terms, textile digital printing on fabric works like printing a photo on paper—but instead of paper, you’re printing on cotton, silk, polyester, or other fabrics.

How Does Textile Digital Printing on Fabric Work?

Here’s a step-by-step breakdown of how textile digital printing on fabric actually happens:

Design Preparation

The process begins with a digital design. It can be created using software like Photoshop or Illustrator. The file is saved in high resolution so the print comes out crisp and clean.Fabric Pre-Treatment

Before printing, the fabric is treated with a coating that helps it absorb the ink evenly. This step ensures bright colors and sharp details.Printing

The digital printer sprays the ink onto the fabric according to the design. Depending on the printer type, it can print on natural fabrics (cotton, silk) or synthetic ones (polyester, nylon).Fixation or Heat Setting

After printing, the fabric goes through a heat or steam process. This fixes the color so it doesn’t fade or wash out.Washing and Finishing

Once the colors are fixed, the fabric is washed to remove any extra chemicals or ink. Then it’s dried and ready for use.

This simple but precise process is what makes textile digital printing on fabric popular across industries.

Types of Textile Digital Printing on Fabric

There are several types of textile digital printing on fabric, depending on the ink and fabric used:

1. Direct-to-Fabric (DTF) Printing

This method prints directly onto the fabric roll. It’s ideal for cotton, silk, or linen. It gives rich colors and a soft feel.

2. Dye-Sublimation Printing

Commonly used for polyester and synthetic fabrics. The ink turns into gas under heat and bonds with the fibers, resulting in long-lasting prints that won’t fade easily.

3. Reactive Printing

Used for natural fibers like cotton or rayon. Reactive dyes give deep, bright colors and excellent wash durability.

4. Pigment Printing

This type uses pigment ink that sits on top of the fabric instead of soaking in. It’s great for home décor or short runs since it doesn’t need much post-processing.

5. UV Printing

UV-curable inks are used on specialty fabrics or blends. It’s a newer technology that’s gaining popularity for technical textiles.

Each of these techniques shows how textile digital printing on fabric can fit almost any fabric type or industry need.

Benefits of Textile Digital Printing on Fabric

There are many reasons why the textile world is shifting toward textile digital printing on fabric. Here are some of the key advantages:

1. Design Freedom

Designers can print any image, pattern, or gradient without limits. You can easily experiment with colors and make quick changes digitally.

2. No Minimum Order

Traditional printing needs screens and setup costs, which make small batches expensive. But textile digital printing on fabric allows even a single piece to be printed economically.

3. Fast Turnaround

Because there’s no plate or screen setup, digital printing saves time. You can go from design to finished fabric in just hours.

4. Eco-Friendly Option

This process uses less water, fewer chemicals, and produces minimal waste. That makes textile digital printing on fabric more sustainable compared to screen printing.

5. High Detail and Quality

Digital printers can reproduce complex designs, gradients, and photographic images with perfect clarity and smooth color transitions.

6. Cost-Effective for Short Runs

When you print smaller quantities, digital printing is far cheaper than traditional methods.

7. Less Fabric Waste

Since it’s a direct printing process, there’s almost no wastage of fabric due to misprints or alignment errors.

Applications of Textile Digital Printing on Fabric

Textile digital printing on fabric is not limited to fashion alone. It’s used in many industries where creativity and customization matter.

1. Fashion and Apparel

From T-shirts and dresses to scarves and sarees, fashion brands rely on textile digital printing on fabric to bring unique designs to life. Designers love it because it allows full creative control and quick production.

2. Home Furnishings

Curtains, bedsheets, cushion covers, and upholstery fabrics often use digital printing for unique patterns and vibrant color schemes.

3. Sportswear and Activewear

Sublimation printing (a type of textile digital printing) is perfect for sportswear because it creates stretchable, durable, and breathable prints that don’t fade or peel.

4. Advertising and Displays

Fabric banners, backdrops, and displays are printed digitally for events and trade shows because they’re lightweight and easy to install.

5. Custom Merchandise

Small businesses use textile digital printing on fabric for tote bags, custom clothing, and other promotional products.

6. Interior Design

Interior decorators use printed fabrics for wall panels, art installations, and furniture covers, giving spaces a personal touch.

Textile Digital Printing on Fabric vs. Traditional Printing

Clearly, textile digital printing on fabric is more flexible, eco-friendly, and suitable for today’s fast fashion and customization trends.

Future of Textile Digital Printing on Fabric

The demand for textile digital printing on fabric is growing fast in India and around the world. With customers wanting personalized designs, shorter production cycles, and sustainable processes, digital printing is expected to dominate textile manufacturing in the coming years.

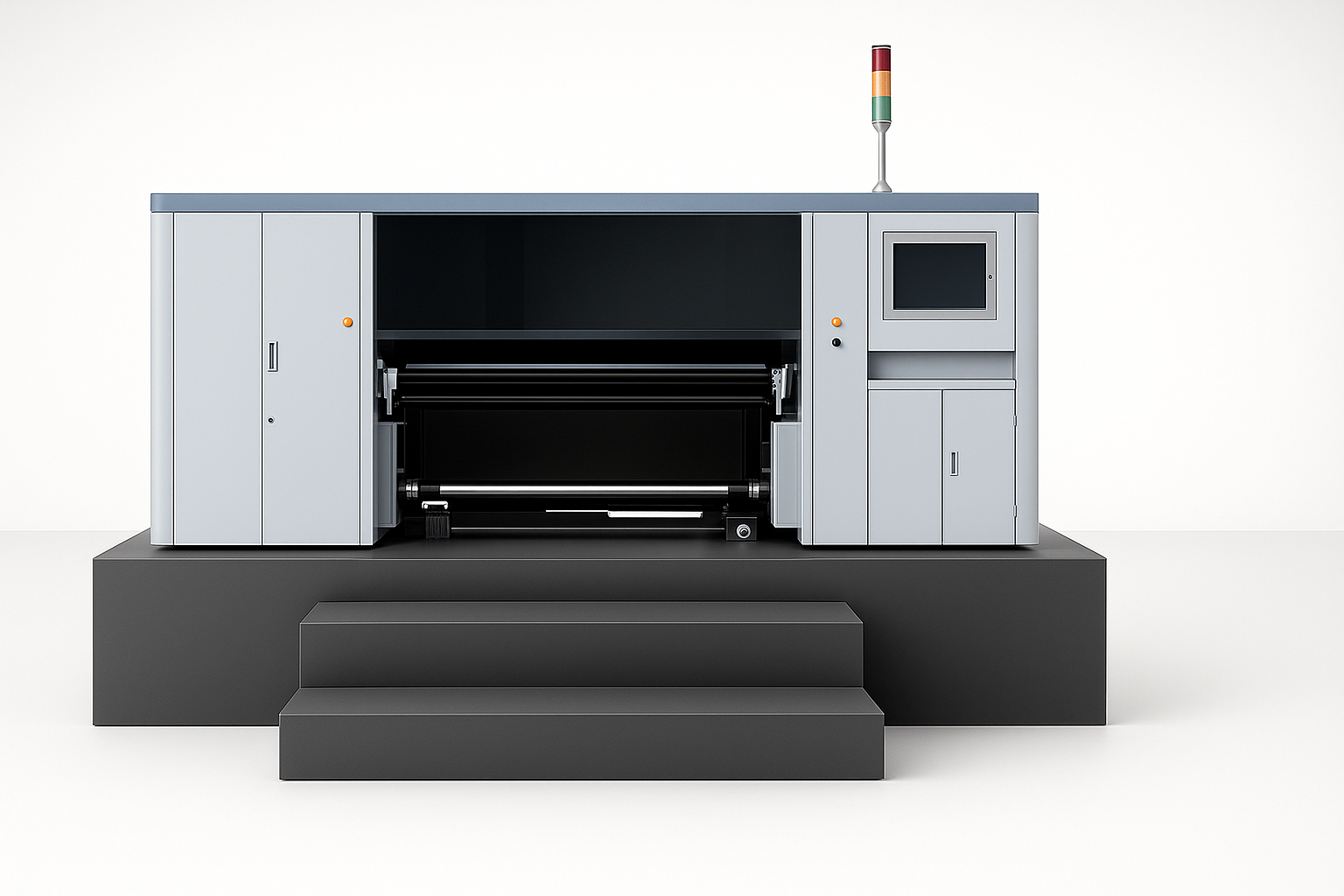

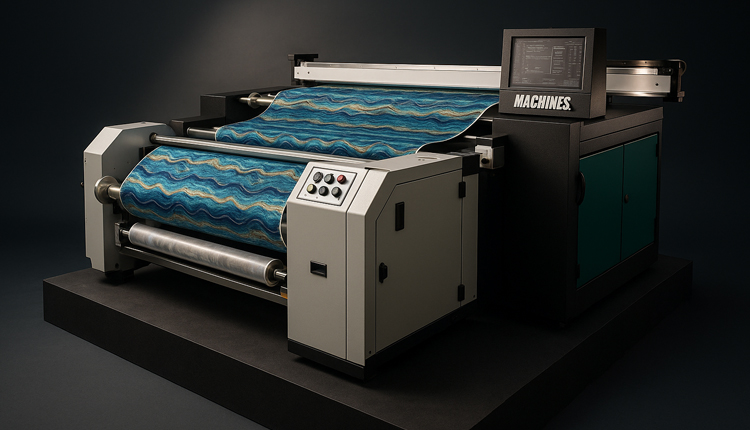

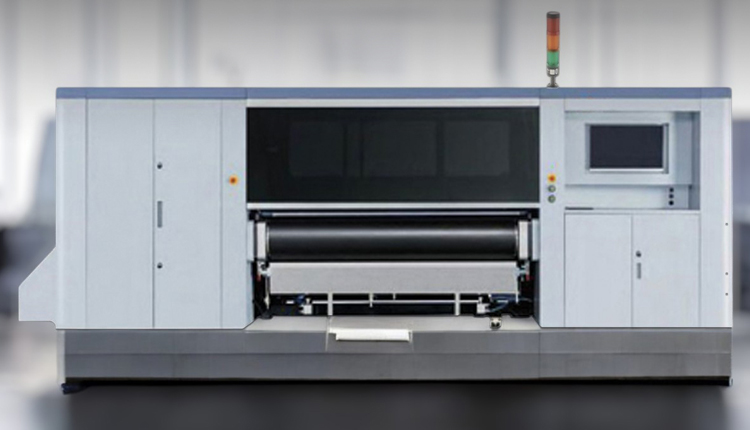

New developments like single-pass digital printers are making printing even faster—capable of printing hundreds of meters per hour. These machines, such as those made by HGS Machines Pvt. Ltd., offer high-speed, high-quality printing with lower operational costs.

As technology improves, we can expect textile digital printing on fabric to replace traditional methods in most industries. The combination of speed, quality, and design freedom is hard to beat.

How to Choose the Right Textile Digital Printer

If you’re a business owner or designer planning to invest in this technology, here’s what to keep in mind:

Type of Fabric You Use – Choose a printer compatible with your main fabric type (cotton, silk, polyester, etc.).

Production Volume – For high production, a single-pass printer is ideal. For smaller runs, a multi-pass printer works fine.

Ink Type – Reactive, pigment, or sublimation inks depending on your fabric and end use.

Color Accuracy – Check if the printer offers advanced color calibration and ICC profiles.

After-Sales Support – Reliable service and easy availability of spare parts are crucial for smooth operation.

A good example is HGS Machines, an Indian manufacturer offering advanced fabric digital printing solutions for all production sizes.

Why Textile Digital Printing on Fabric Is a Smart Choice

Here’s a simple summary of why more textile businesses are switching to digital:

Saves time and cost for small to medium orders

Offers unmatched design flexibility

Reduces water and chemical use

Enables quick sampling and faster delivery

Gives consistent, high-quality results

Supports sustainable production

In short, textile digital printing on fabric allows creativity and efficiency to work together—something traditional methods struggle to achieve.

Final Thoughts

The textile industry is changing rapidly, and textile digital printing on fabric is leading this change. Whether it’s fashion designers, home décor brands, or promotional product makers—everyone is embracing this technology for its speed, quality, and sustainability.

If you want to stay ahead in the market, adopting textile digital printing on fabric isn’t just a smart move—it’s becoming a necessity. It saves resources, offers endless design options, and meets the growing demand for customized, eco-friendly fabrics.

From colorful sarees to designer curtains, from sportswear to luxury apparel—textile digital printing on fabric is redefining how we create and experience textile designs.

FAQs on Textile Digital Printing on Fabric

Q1. What is textile digital printing on fabric?

It’s a process that uses digital printers to print designs directly onto fabric using special inks.

Q2. Is digital printing suitable for all types of fabrics?

Yes, depending on the printer and ink type, it can be used for cotton, silk, polyester, and blends.

Q3. How long do digital prints last on fabric?

With proper fixation and care, digital prints are long-lasting and fade-resistant.

Q4. Is textile digital printing on fabric eco-friendly?

Yes, it uses less water, energy, and chemicals than traditional printing.

The cost depends on the printer type, fabric, and design complexity, but it’s cheaper for small runs compared to screen printing.