The textile industry has changed a lot in the last decade. From traditional block printing to advanced digital systems, printing technology now defines speed, quality, and profit in the fabric business. One of the biggest reasons behind this progress is the industrial fabric printing machine.

If you are part of the textile manufacturing sector, you already know how printing can decide your product’s success. A good printing machine brings color accuracy, fine detailing, and production efficiency. In this guide, we’ll explain everything about the industrial fabric printing machine — how it works, its types, benefits, and why it’s a smart investment for modern textile units.

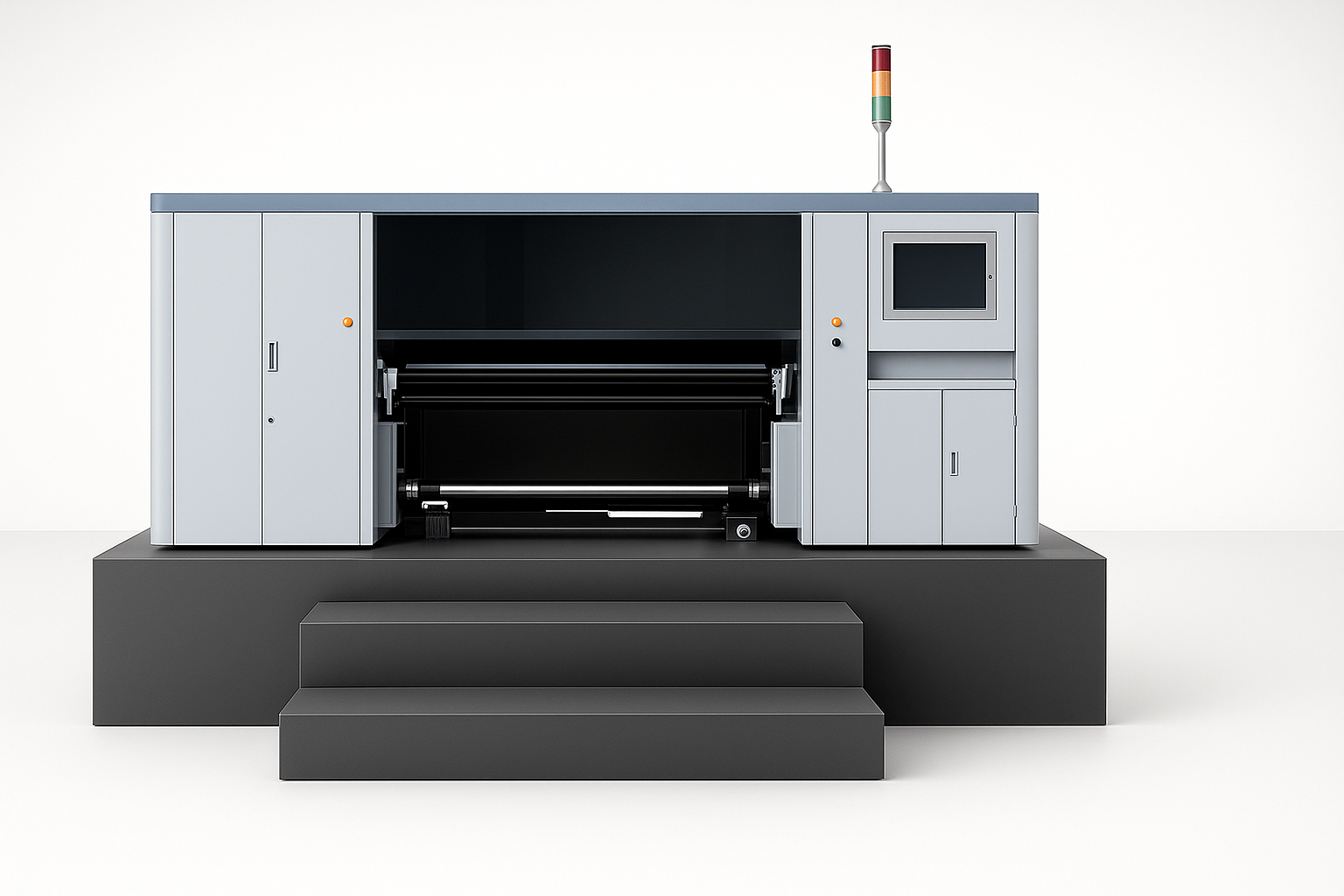

What is an Industrial Fabric Printing Machine?

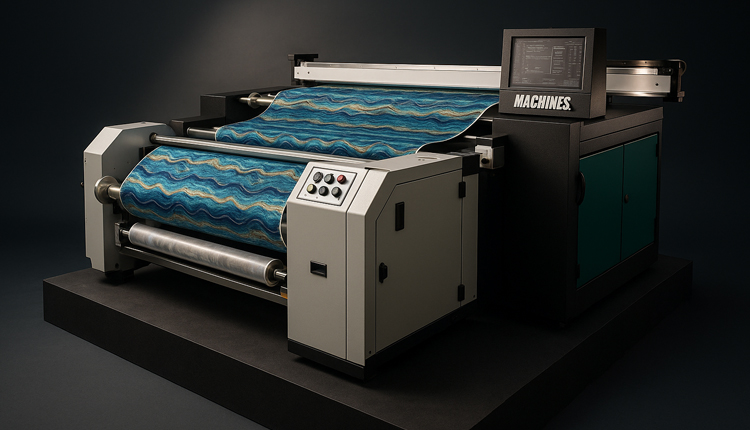

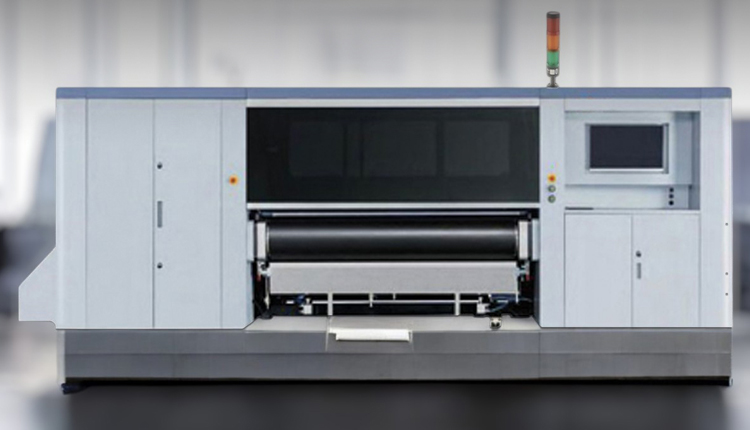

An industrial fabric printing machine is a high-capacity digital printer designed to print designs directly onto fabric rolls or sheets. Unlike traditional screen printing that uses patterns and dyes manually, this machine uses digital printheads to apply ink with precision and speed.

These machines can print thousands of meters of fabric in a day, making them ideal for:

Garment manufacturing units

Textile export houses

Home décor fabric producers

Saree and dupatta printing

Upholstery and curtain fabric printing

The goal of an industrial fabric printing machine is simple — deliver high-quality prints, faster production, and reduced wastage.

How Does an Industrial Fabric Printing Machine Work?

The process looks simple but involves advanced engineering. Here’s a step-by-step breakdown:

Design Preparation

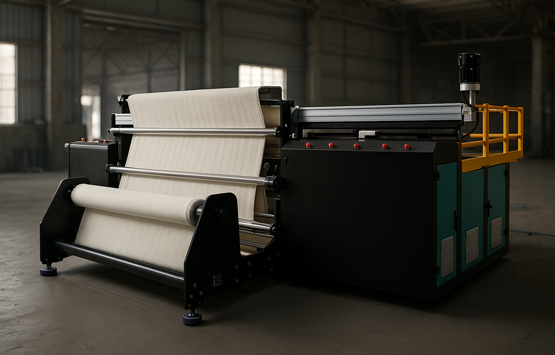

The artwork or design is created digitally using software like Photoshop or CorelDRAW. It is then processed through a RIP (Raster Image Processor) to convert the design into machine-readable data.Fabric Loading

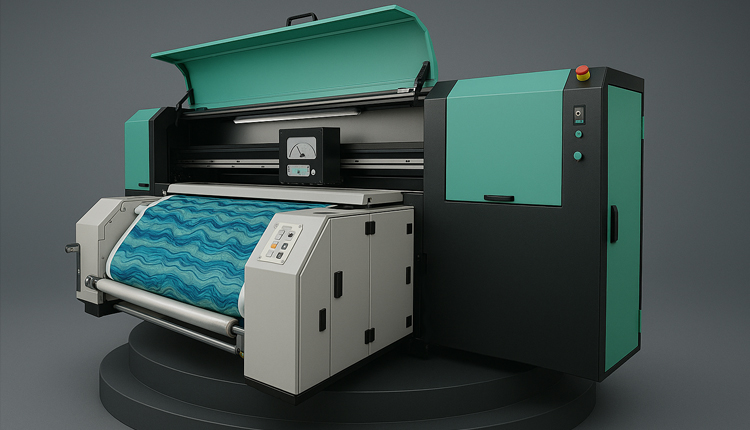

The fabric roll is mounted on the machine. The fabric must be properly tensioned to ensure perfect alignment during printing.Inkjet Printing

The industrial fabric printing machine sprays micro-droplets of ink directly onto the fabric using printheads (Epson, Ricoh, or Konica). Each printhead contains thousands of nozzles that control color mixing and accuracy.Drying & Fixation

Once printed, the fabric passes through a heater or curing chamber. This step fixes the color permanently, making it wash-resistant.Finishing

The printed fabric is collected, inspected, and prepared for cutting or stitching.

This automated process ensures uniform quality and color consistency for every meter printed.

Types of Industrial Fabric Printing Machines

Choosing the right industrial fabric printing machine depends on your business size, fabric type, and production goals. Below are the main types available in the market.

1. Pigment Printing Machines

These use pigment inks suitable for cotton, linen, and blends. The biggest advantage — no need for washing or steaming after printing. Perfect for short runs and fast delivery orders.

2. Reactive Printing Machines

Reactive dye-based industrial fabric printing machines give brighter and more durable prints on natural fibers. However, they require post-processing like steaming and washing.

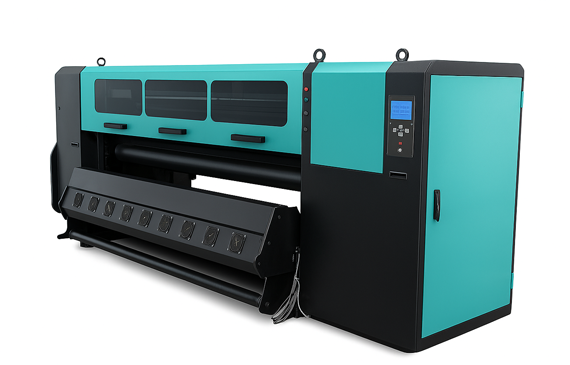

3. Disperse & Sublimation Printing Machines

Best for polyester fabrics. Sublimation-based machines print on transfer paper, which is later heat-pressed onto fabric. It’s commonly used for sportswear, banners, and interior décor.

4. Direct-to-Fabric (DTF) Printers

These machines print directly on fabric, skipping transfer paper. They are great for bulk textile printing and save time.

5. Hybrid Industrial Printing Machines

These combine multiple technologies — for example, reactive and pigment in one machine — giving flexibility for mixed fabric orders.

Why Textile Businesses Prefer Industrial Fabric Printing Machines

The shift from manual to industrial fabric printing machines happened because of three major needs: speed, consistency, and cost efficiency.

1. High-Speed Production

Industrial machines can print hundreds of square meters per hour. This speed helps meet large export orders and short delivery timelines.

2. Sharp Detailing and Color Accuracy

Digital printing heads produce tiny droplets — as small as 5 picoliters — ensuring sharper details and vibrant colors.

3. Lower Wastage

Since designs are digitally controlled, you print only what you need. This saves ink, fabric, and energy.

4. Customization Made Easy

Unlike screen printing, which needs separate screens for every color, digital industrial fabric printing machines allow endless customization with no extra setup time.

5. Eco-Friendly Printing

Most modern printers use water-based inks that are safe for the environment and reduce chemical waste.

6. Easy Maintenance and Operation

These machines come with user-friendly panels and automatic cleaning systems, reducing downtime.

Industrial Fabric Printing Machine Features You Should Look For

Before buying, check for these features:

Printhead Type: Epson, Ricoh, or Konica heads are standard in the industry.

Printing Speed: Choose based on your order size.

Color System: CMYK, CMYK+White, or extended color systems.

Ink Type: Pigment, reactive, or sublimation depending on your fabric.

Fabric Compatibility: Cotton, silk, polyester, viscose, or blends.

Software Support: RIP software compatibility ensures accurate color management.

After-Sales Support: Spare parts and service availability in your region.

A good industrial fabric printing machine should balance speed, quality, and reliability.

Advantages of Using Industrial Fabric Printing Machines

Let’s look at the benefits that make these machines a favorite among textile manufacturers:

1. Continuous Printing

You can print 24/7 with minimal human supervision. Most machines support roll-to-roll operation.

2. Consistent Output

No matter how many meters you print, the color and pattern remain the same throughout the batch.

3. Reduced Labor Cost

Automation reduces dependency on skilled printers. One operator can handle the entire machine.

4. Multi-Fabric Support

With the right ink type, a single industrial fabric printing machine can print on cotton, silk, polyester, or blended textiles.

5. Fast Design Change

You can switch from one design to another instantly — perfect for fashion or seasonal trends.

6. Digital Storage

Designs are stored digitally, making reorders simple and error-free.

Industrial Fabric Printing Machine vs Traditional Screen Printing

It’s clear that for today’s textile industry, an industrial fabric printing machine is the smarter choice.

Applications of Industrial Fabric Printing Machines

Fashion and Apparel Printing — T-shirts, sarees, dresses, scarves.

Home Furnishing — Curtains, sofa covers, bed sheets.

Sportswear & Activewear — Sublimation printing on polyester.

Industrial Textiles — Flags, banners, and technical fabrics.

Custom Design Printing — Personalized fabric runs for designers or small brands.

Whether you’re a manufacturer or a startup brand, using an industrial fabric printing machine gives you control over creativity and production.

Maintenance Tips for Industrial Fabric Printing Machines

Proper care ensures long life and consistent output:

Clean printheads regularly to prevent nozzle blockage.

Maintain stable room temperature and humidity.

Use only recommended inks and cleaning solutions.

Calibrate the machine periodically for accurate color.

Store fabric rolls properly to avoid wrinkles or dust buildup.

Following these steps can extend the life of your industrial fabric printing machine and reduce downtime.

How to Choose the Best Industrial Fabric Printing Machine

When buying, ask these questions:

What is the maximum print width and speed?

What fabric types are supported?

What’s the warranty and service support period?

Are spare parts and inks easily available?

Can the machine be upgraded with more printheads later?

If you’re in India, brands like HGS Machine provide a full range of industrial fabric printing machines suitable for startups and large manufacturers alike.

Future of Industrial Fabric Printing

The next few years will bring smarter, faster, and more sustainable printing systems. AI-based color calibration, IoT monitoring, and eco-inks are becoming standard in modern industrial fabric printing machines.

Manufacturers who adopt these machines early will stay ahead in productivity and quality.

Conclusion

The industrial fabric printing machine has become the backbone of modern textile manufacturing. It replaces manual labor with automation, improves design accuracy, and supports bulk production without compromising quality.

Whether you run a small design unit or a large textile factory, investing in an industrial fabric printing machine means faster delivery, lower costs, and happier customers.

If you are planning to upgrade your printing setup, explore modern machines with high-speed printheads, flexible ink systems, and reliable after-sales support. With the right equipment, your fabric printing business can achieve both quality and growth.

FAQs

1. What is an industrial fabric printing machine?

An industrial fabric printing machine is a high-speed printer used to print designs directly on fabric rolls for mass production.

2. Which fabrics can be printed using an industrial fabric printing machine?

You can print on cotton, polyester, silk, viscose, and blended fabrics depending on the ink type.

3. How is industrial fabric printing better than traditional printing?

It’s faster, more precise, and cost-effective, with minimal setup and waste.

4. How much does an industrial fabric printing machine cost?

Prices vary based on model and printheads, usually ranging from ?10 lakh to ?60 lakh.

5. Do I need special inks for an industrial fabric printing machine?

Yes, use inks designed for your fabric type — pigment, reactive, or sublimation.