If you're looking to grow your textile business or start custom fabric printing, choosing the right fabric printing machine is essential. Whether you need a textile printer, a digital fabric printing machine, or a high speed textile printer, understanding the options will help you make the right decision. This guide explains different textile printing machines, their uses, costs, and what makes a textile fabric printing machine suitable for your business.

What Is a Fabric Printing Machine?

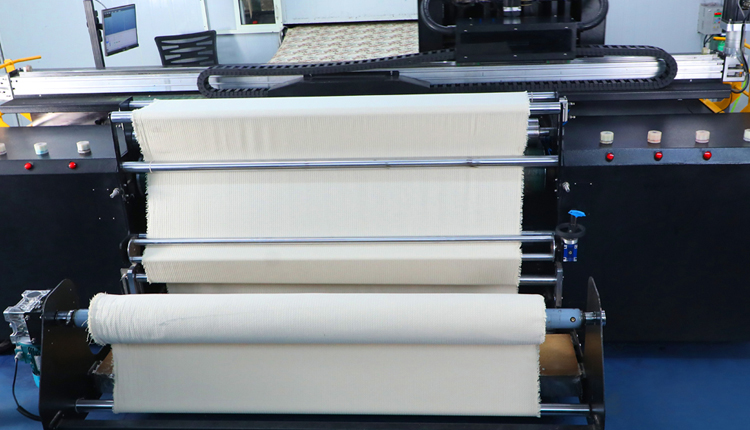

A fabric printing machine is used to apply ink, patterns, or designs directly to fabric. There are different types of fabric printing machines, including textile printers, industrial fabric printing machines, and digital textile fabric printing machines. Modern fabric printing equipment offers precise results, faster output, and better efficiency. If you are comparing machines for your business, it’s important to consider whether you need a pigment based digital fabric printer, a high speed textile printer, or a standard textile printer.

Types of Textile Printing Machines

Choosing the best textile printing machine depends on your production needs. Below are the common types of textile printers and fabric printing machines used across industries.

1. Digital Textile Fabric Printing Machine

A digital textile fabric printing machine uses inkjet technology to print designs directly onto textiles. This type of textile printer is ideal for short runs, custom designs, and high-resolution output.

Good for cotton, silk, polyester

Uses pigment, reactive, or sublimation inks

Minimal setup time

Supports quick design changes

2. Industrial Fabric Printing Machine

An industrial fabric printer is built for large-scale production. It supports wide-format rolls and high-volume printing. If you are producing thousands of meters daily, an industrial fabric printing machine will meet your needs. Popular models include machines equipped with Ricoh Gen6 printheads for speed and accuracy.

A pigment based digital fabric printer is popular for printing on cotton, canvas, and natural fabrics. It doesn’t require steaming or washing, which makes it cost-effective and efficient. This fabric printing machine is often used in home textiles, tote bags, and printed apparel.

Fabric Printing Machine Cost

The fabric printing machine cost varies by type, brand, and features.

Machine Type Entry-Level Textile Printer Mid-Range Textile Printing Machine

Price Range (INR) ₹5–10 lakh ₹12–25 lakh

Use Case Small business, low volume Medium production

Textile Printing Near Me: Local vs Imported Machines

When searching for textile printing near me, you’ll find both local and imported options for textile printing machines. Local Fabric Printing Machines Lower price Easy availability of parts Suitable for beginners Imported Textile Printers Advanced features Better speed and accuracy Ideal for commercial and export printing For professional-grade printing, many businesses invest in industrial fabric printing machines from global manufacturers. However, for cost-conscious startups, a locally made textile printer is often a practical choice.