Introduction

The world of fabric printing has moved far beyond traditional methods. Today, textile digital printing on fabric is the go-to choice for businesses that want precision, speed, and flexibility. Whether you’re a small workshop or a large-scale unit, investing in a fabric printing machine can transform your production. Companies like HGS Machines are leading this change by offering advanced textile printers, ranging from entry-level models to fully automated industrial fabric printing machines. In this blog, we’ll explain how textile digital printing works, the benefits it offers, the role of machines like those from HGS, and what you should know about fabric printing machine cost when selecting the best textile printer for your business.

What Is Textile Digital Printing on Fabric?

Textile digital printing is the process of applying designs directly onto fabrics using a textile printer. Unlike traditional screen printing, which needs plates and stencils, digital printing uses computer-controlled printheads to jet ink directly on the cloth. It works across different fabric types—cotton, polyester, silk, viscose, blends—and supports various ink technologies such as reactive, sublimation, and pigment inks. With a textile fabric printing machine, you can produce everything from detailed patterns for fashion to bold designs for home décor. This method saves time, reduces waste, and ensures highly detailed results. That’s why it’s replacing older methods in many parts of the garment and textile industry.

Why Choose Digital Printing Over Traditional Methods?

Switching to digital printing with a modern textile printing machine offers several benefits: Flexibility in Design – You can print multiple colors and complex graphics without limits. No Setup Hassle – No screens or plates required, making it ideal for small batches and sampling. Eco-Friendly Process – Uses less water, fewer chemicals, and minimizes ink wastage. Faster Turnaround – Quick setup means you can complete orders faster, increasing efficiency. High Precision – The latest industrial fabric printers ensure sharp edges, consistent shades, and smooth gradients. These benefits make digital the future of textile printing.

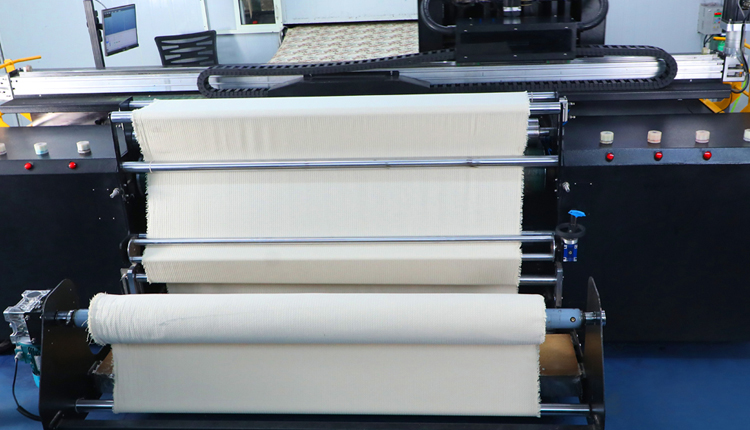

Components of a Fabric Printing Machine

A fabric printing machine isn’t just a printer—it’s a system designed for seamless fabric handling and color application. Some of the key parts include: Printheads: The heart of a textile printer. For example, HGS uses Ricoh Gen6 heads that provide high resolution with variable drop sizes. Ink System: Designed to handle different ink types like pigment, sublimation, or reactive inks. Fabric Feeding System: Ensures the cloth stays aligned during printing using conveyor belts and tension controls. Drying Units: Quick-dry systems help fix colors and improve production speed. Cleaning System: Automatic cleaning units reduce downtime and extend the life of the printer. All these components work together in a textile fabric printing machine to deliver reliable, industrial-grade results

HGS Machines: A Leader in Industrial Fabric Printers

HGS Machines has built a strong reputation in the digital textile printing industry. Their range of industrial fabric printing machines caters to businesses of all sizes.

Product Range

Ricoh-Tejas: Entry-level model with 4 printheads. Compact, easy to use, and perfect for small to medium businesses.

Chrome: 8-head machine, suitable for units needing higher production speeds.

Huegush: 16-head printer designed for medium to large production facilities.

Blaze: High-end, 32-head industrial fabric printer built for bulk production.

Key Features of HGS Machines

Advanced Printheads: Equipped with Ricoh Gen6 technology for superior color reproduction. User-Friendly Design: Plug-and-play systems with preloaded RIP software. Smooth Fabric Handling: Automatic tension control and conveyor-driven systems reduce misprints. Efficient Ink Systems: Optimized for minimal waste and maximum uptime. Training & Support: HGS provides operator training and responsive service, ensuring clients get the most from their machines.

With these features, HGS ensures that their printers are not just machines but long-term business assets.

Best Textile Printer: What to Look For

When searching for the best textile printer, you should evaluate based on:

Print Speed – Does it meet your production needs?

Print Quality – Can it deliver high-resolution, detailed prints?

Ink Compatibility – Does it support the fabrics and inks you work with?

Durability & Support – Is the manufacturer offering training, warranty, and quick service?

Scalability – Can the machine grow with your business demands?

HGS ticks all these boxes, making them a trusted choice for those seeking the best textile printer in the industry.

Fabric Printing Machine Cost: What to Expect

The fabric printing machine cost depends on several factors: Printhead Count: More heads mean faster speeds but also higher cost. Machine Size & Features: Large industrial setups with dryers and automation cost more. Ink Technology: Pigment and sublimation machines may vary in price. After-Sales Support: Training, service, and warranty packages add value. While HGS does not list prices publicly, most industrial fabric printing machines range from a few lakhs to several crores depending on configuration. For exact pricing, businesses are encouraged to contact HGS directly.

Why Choose HGS for Industrial Fabric Printing Machines?

Wide Range of Options: From budget-friendly to high-capacity models.

Proven Performance: Trusted by many textile units across India.

Eco-Friendly Focus: Water-based inks and energy-efficient designs.

Local Support: Quick, on-call service across the country.

Scalable Solutions: Suitable for startups, growing businesses, and large manufacturers.

By combining innovation with service, HGS helps businesses get the most out of their investment in a textile fabric printing machine.

Textile digital printing is reshaping the industry, giving businesses the freedom to experiment with designs while reducing costs and environmental impact. Whether you’re looking for a small printer fabric solution or a large industrial fabric printing machine, the right choice can help you meet growing market demands. HGS Machines stands out as a reliable partner in this space. With their advanced technology, range of options, and strong support system, they provide some of the best textile printers available today. If you’re considering a move into digital printing, or want to upgrade your current setup, HGS offers the machines and expertise to get you there.

FAQ

Q1. What is textile digital printing on fabric?

Textile digital printing is the process of directly printing digital designs onto fabrics using a textile printer.

Q2. What is the cost of a fabric printing machine?

Fabric printing machine cost varies by model and features, ranging from a few lakhs to several crores.

Q3. Which is the best textile printer for business?

The best textile printer is one that balances speed, print quality, and cost—HGS Machines offers reliable options for all needs.

Q4. What is an industrial fabric printing machine?

An industrial fabric printing machine is a large-scale digital printer designed for high-volume fabric production.

Q5. How does a textile printer work?

A textile printer uses inkjet printheads to apply inks directly onto fabric with high precision.

Q6. Why choose HGS Machines for fabric printing?

HGS Machines provides advanced textile printers with strong after-sales support and scalable solutions.